Intima Asia

Natural dyes have always been used in textiles and still are in areas such as Peru. Thus, the rising sustainability consciousness and desire for nontoxic body-friendly solutions results in a variety of do it yourself “green” dyes easily available on line. A group of Chinese researchers have specialized in fruit dye and have managed carry out this process on a larger scale. Intima Asia wanted to find out more about their achievements.

An Emerging Trend

The only existing fashion clothing collection already available to consumer seams to be the Clean Color capsule by Patagonia, comprising of T-shirts, sweatshirts, pants, shorts and jackets, naturally dyed with indigo for blues, cochineal beetles for reds, pomegranate for yellows and browns as well as, the much less poetic, Chinese silkworm excrements for greens. Natural dyes are of course less resistant then their chemical counterparts but are much cleaner and can give clothes a rather unique “alive” look that, with washing, changes over time, creating new design possibilities. Besides this example, there are numerous testing and research projects in progress at the moment around the world but the following is one of the most advanced. Its distinguishing feature? It only uses fruit.

Drinkable Dye

It is in the Chinese city of Foshian, in Guandong province, that Mr. Chi-Bin He, the CEO of small company , Lingyu Clothing Co., LTD has successfully developed “Fruit Dye”. It took them eight years of continuous researches and experiments on various fruits before attaining the desired results and starting to offer their products to the market. This new technology redefines the boundaries of ecological textiles and opens the way for a variety of applications. It is now possible to produce colored fabrics with just pure fruit juice, without adding any chemical substances. “The dyeing and finishing process is done without adding any chemical auxiliaries and chemical pigments, the finished fabric meets the standard of GB18401-2010 and GB31701-2015. Moreover, the dyeing liquor grade reaches the level of Chinese Standard--GB 19297-2003 - the hygienic standard for fruit and vegetable juice beverages!" say the inventors. Ecological and skin-friendly, fruit dyed textiles are particularly suitable for infant clothing, children's wear, underwear, leisure wear but also bedding, basically any textile meant to be in direct contact with the human body.

Save Water

We all know that despite the enormous efforts dome by the mills, chemical dyeing still needs a lot of water and, in many cases, still produces a large amount of waste. “Dyeing 1 kg textiles with traditional chemical dye needs up to about 50 to 150 liters of water, which means tens of millions of tons of water every year… Fruit dye only needs about 1.5 liters of water, which can save tens of millions of tons of clear water, and create a much greater benefit for our earth's water resources” argues the producer. ”Ordinary textiles usually use traditional chemical dyeing which produces tens of millions of tons of mixed chemical agent wastewater. Dyeing wastewater contains a large number of harmful substances: sodium sulfide, aniline, copper sulfate, formaldehyde, cyanide, etc., if we do not handle it well, it will seriously damage our earth’s ecological environment, and also cause harm to the human’s health. Fruit dye, which is the natural dyeing alternative will not produce any chemical wastewater.”

Fibers and Colors

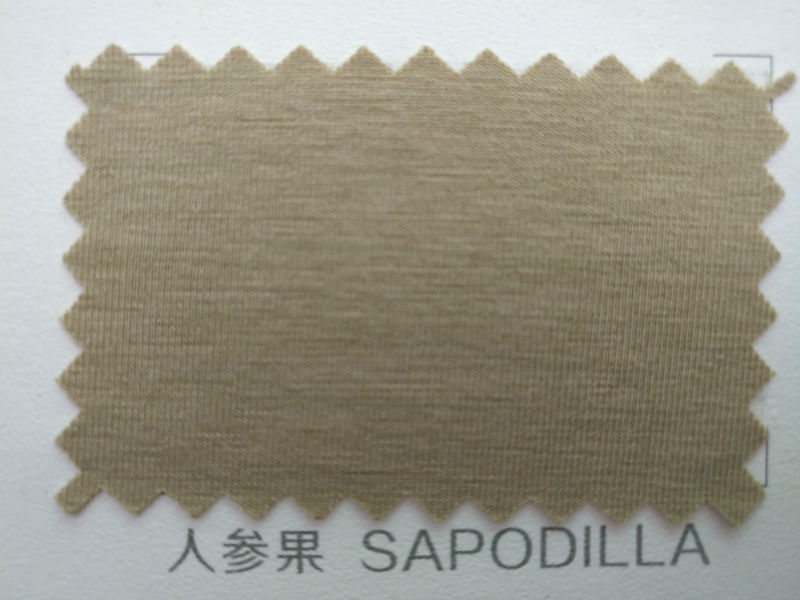

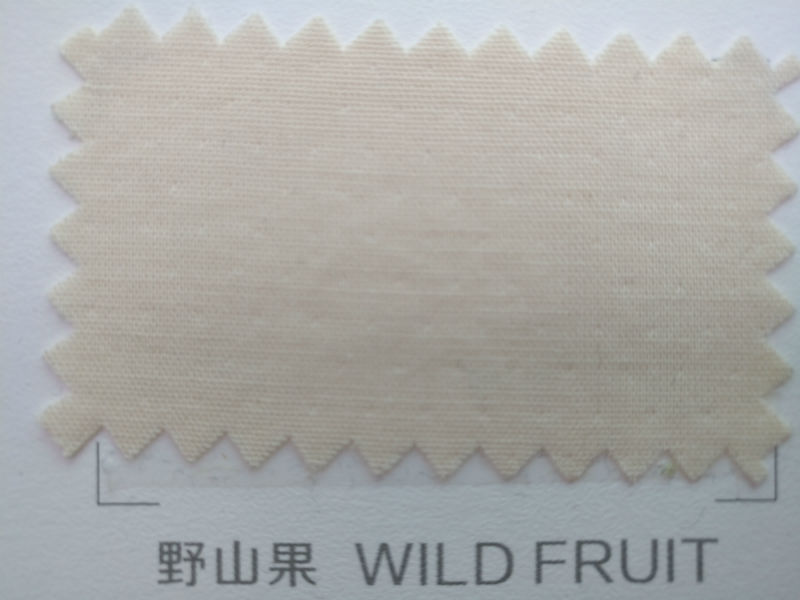

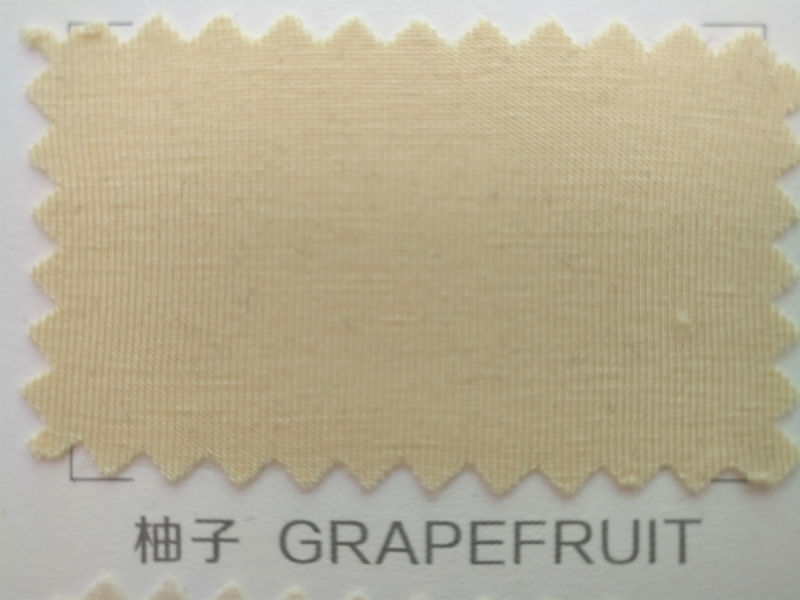

Of course, only natural fibers can be fruit dyed: pure cotton, natural silk, hemp, bamboo, corn, alongside cellulosic fibers such as Tencel, Modal are suitable. Currently, more than ten colors have been successfully developed but, “we still need to constantly supplement more product testing results to reach to the new color of class A.” says the company representative. At the moment colors are made from: apples, bananas, pitayas, oranges, star fruits, mangosteens, longans, lemons, grapefruits, wild berries, coconuts and sapodillas but a variety of lighter or darker shades are possible thanks to various combinations.

Product Certification

After nearly one year of joint research by Guang-Fang Detection and Measurement Technique Co. LTD. of Guangdong province, Jiang-Nan University, Xi’an Polytechnic University, and Ling-Yu Clothing Co. of Foshan, Guangdong province, a fruit dye product identification chart is taking shape and will, very soon, become the national industry standard.

The fruit dye industry’s supply chain including scientific research, production, sales, and service and the whole industrial chain including seedling cultivation, agricultural plant, fiber, spinning, weaving, clothing manufacture, brand, and the third party service providers are setting up the “Fruit Dye Industry Alliance”: “The green innovation development of fruit dye, can both enhance the power of brands and increase the added value of products, but is it also a strong social responsibility for the entrepreneurs of the Fruit Dye Industry Alliance.”

How Does it Work?

Once mature, fruits are collected and stored, then the juice is extracted and the formulation made according to the shade desired. The fabric is pre-treated before dyeing, then finished. The final result depends on the fruit combination, the kind of fabric used and the state of natural light. Fruit dye adopts an innovative dye process, which is to dye in normal temperature, without consuming steam, without any chemical additives and chemical pigments, and without sewage disposal during the whole dye process.

Which Intimate Apparel Companies are Working on it at Present?

We have not extended our project to intimate apparel companies yet. At the moment our main clients are in the children’s textile industry with the highest request for quality. These companies are very famous brands such as Little Star Group—with its own brands of Yeehoo, Peekaboo, Pincopallino, as well as Silver Cross, Philips Avent, Stokke and Jinfa Labi Woman Infant Child Garment Co. LTD—with its own brands “Labi”, “I LOVE BABY”, “Baby Labi” to name just a few...

Because of the limited capacity of Fruit Dye, we will formally collaborate with some professional intimate apparel companies from Spring 2018.

What are the Major Problems you are Facing in using This New Process in the Intimates Industry?

The major problem we are facing when it comes to using this new process for the intimates industry is temperature control during production. The feature of fruit dye product is pure natural, health, and comfort. A layer of natural active pectin is formed on the fabric surface after dyeing, which provides a unique soft gloss, and increases moisture absorption and freshness for a superior skin comfort. The pigment from natural fruit looks its best in natural light, which makes the color of fruit dyed products pleasing. In order to avoid destroying the advantages of fruit dye, the ironing temperature cannot be too high, as with any pure silk product.

Are There Some Mills Using Fruit Dye Yet?

No, there are none. At the moment the production patent and registered trademark exclusively belong to Lingyu Clothing Co. LTD of Foshan, only Lingyu Clothing Co. LTD od Foshan produced fruit dye fabrics.

How Many Washes can Fruit Dye Allow?

According to the international quality acceptance standard, the color fastness after washing is at level four, meaning that color can last for over two years.

Towards a Cleaner Future

We cannot solve the entire problem of chemical color pollution at the moment, but through strongly promoting fruit dye, firstly from underwear and home textiles, we can eradicate a part of the problem which will make great contribution to the ecological industry. Therefore, although the production patent and registered trademark are exclusive to Lingyu Clothing Co. LTD of Foshan, in order to promote higher social responsibility the Industry Alliance was built thanks to Industry-University-Research cooperation and innovation in 2016.

More consumers will only be able to use green environment protection health products if more enterprises get involved in ecological development, allowing the fruit dyeing project, the product of eight years of continuous R&D, to truly demonstrate its social value.

“Supporting green and clean production, promoting green reformation for traditional manufacturing, and helping to build an industry system with green, low-carbon, and recycling development” is the major trend at the moment.

Planting fruit trees in a wide range of countryside with natural environmental protection and only collecting fruits without cutting trees, can greatly reduce the pollution during traditional textile and clothing production’s dyeing processes. This stands to benefit farmers by planting fruit trees for raw material of fruit dye, which creates a virtuous ecological cycle from agriculture, industry, to consumer.

Intima Media Group will join the Alliance by the end of the current year.

Members of The Fruit Dye Alliance

Lingyu Clothing Co. LTD of Foshan, Guangdong Province, P. R China

Guang-Fang Detection and Measurement Technique Co. LTD. of Guangdong Province

Yue-Di-Wei Clothing Co., LTD of Guangzhou, Guangdong Province

Hui-Mian Cotton and Clothing Co., LTD of Fosha

De-Fu-Lun Company of Textile Control Group of Shanghai

Run-Li Textile and Clothing Co. LTD of Fosha

Little Star Grou

Shenzhen Underwear Association

Jiang-Nan Universit

Xi 'an Polytechnic University

Copyright 2024. All rights reserved - Terms